Construction errors rarely originate from poor workmanship alone. In most cases, the root cause can be traced back to documentation gaps, unclear details, or uncoordinated drawings produced long before materials ever reach the site. Shop drawings sit at the center of this issue. When they are incomplete, inaccurate, or poorly coordinated, errors become inevitable. When they are professionally prepared, they act as a powerful risk-control mechanism that protects schedules, budgets, and reputations.

In the U.S. construction industry—where projects face tight deadlines, strict inspections, and high financial exposure—professional shop drawings are one of the most effective tools for preventing costly delays and rework.

The Real Cost of Construction Errors and Delays

Construction errors have consequences that extend far beyond immediate repair costs. Delays triggered by incorrect shop drawings often ripple through multiple phases of a project, affecting labor scheduling, material procurement, and contractual obligations.

When errors occur, they typically result in:

- Lost labor hours due to halted work

- Fabrication rework or material replacement

- Schedule compression that increases overtime costs

- Strained relationships between contractors, owners, and consultants

- Increased exposure to claims and disputes

Professional shop drawings help eliminate these risks by addressing constructability issues early—before fabrication or installation begins.

How Inaccurate Shop Drawings Lead to Fabrication Errors

Fabrication relies entirely on shop drawings as the final source of truth. If those drawings contain errors or ambiguities, fabricators are forced to make assumptions—often with irreversible consequences.

Common fabrication-related issues caused by poor shop drawings include:

- Incorrect dimensions leading to components that do not fit on site

- Misaligned bolt holes or connection details

- Incompatible material specifications

- Missing tolerances that affect assembly

Because fabricated components are often produced off-site, correcting these mistakes can require complete remanufacturing. Professionally prepared shop drawings provide fabrication-ready clarity, eliminating guesswork and minimizing waste.

Installation Delays Caused by Unclear or Uncoordinated Drawings

Even when fabrication is accurate, installation can be severely disrupted by shop drawings that lack coordination between trades. On-site crews depend on shop drawings to sequence their work efficiently and safely.

Poorly coordinated drawings often result in:

- Structural elements conflicting with MEP systems

- Insufficient clearance for installation or maintenance

- Field modifications that compromise design intent

- Delays while teams wait for revised drawings or approvals

Professional shop drawing teams perform coordination reviews that align structural, architectural, and MEP elements before installation begins, ensuring smooth execution on site.

The Role of Constructability Reviews in Error Prevention

Constructability reviews are a critical component of professional shop drawing services. These reviews evaluate whether a design can be built efficiently under real-world conditions.

A thorough constructability review considers:

- Access and installation sequencing

- Tolerances and field conditions

- Trade coordination and spatial constraints

- Safety considerations during erection or installation

By identifying issues that may not be obvious in design drawings, professional shop drawings transform theoretical designs into practical construction solutions.

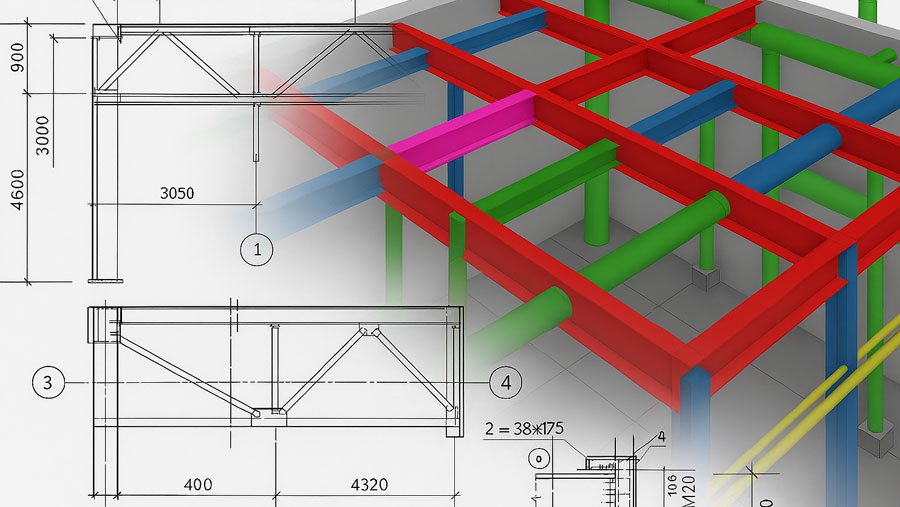

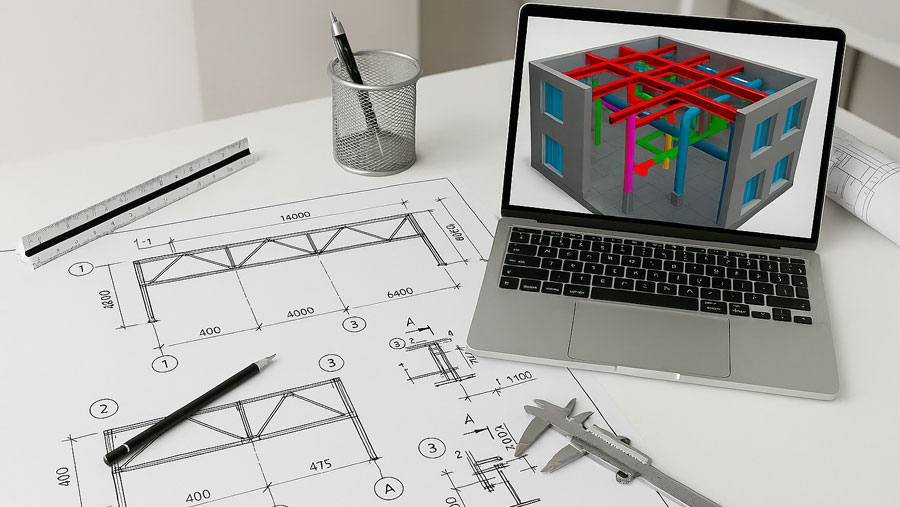

How 3D Modeling and BIM Reduce Errors Before They Occur

Advanced 3D modeling and Building Information Modeling (BIM) have significantly improved the accuracy and reliability of shop drawings. Unlike traditional 2D drafting, 3D models allow teams to visualize the project as an integrated system.

Key benefits include:

- Early clash detection between structural, architectural, and MEP elements

- Clear visualization for reviewers and inspectors

- Improved coordination during fast-track projects

- Enhanced communication between project stakeholders

By resolving conflicts digitally rather than physically on site, professional shop drawings dramatically reduce rework and schedule disruption.

Reducing RFIs and Approval Delays Through Clear Documentation

Requests for Information (RFIs) are often symptoms of unclear or incomplete drawings. Excessive RFIs slow decision-making, delay fabrication, and create administrative overhead.

Professional shop drawings reduce RFIs by:

- Providing complete dimensions and specifications

- Clearly defining connections and interfaces

- Aligning with approved design intent

- Anticipating reviewer concerns

Clear, well-documented shop drawings move through approval processes faster, keeping projects on schedule.

The Importance of Professional Engineers in Shop Drawing Accuracy

Professional Engineers (PEs) play a vital role in validating shop drawings, particularly for structural and load-bearing systems. Their involvement ensures technical accuracy and code compliance.

PE oversight helps:

- Confirm structural integrity and load paths

- Ensure compliance with U.S. building codes and standards

- Reduce the risk of rejected submittals

- Increase confidence among owners and inspectors

In complex or high-risk projects, PE involvement is often the difference between smooth approvals and costly redesigns.

Professional Shop Drawings as a Schedule Management Tool

When properly executed, shop drawings actively support schedule control rather than hinder it. They enable parallel workflows where fabrication, procurement, and installation can proceed with confidence.

Benefits to scheduling include:

- Predictable fabrication timelines

- Reduced on-site disruptions

- Better coordination between trades

- Fewer last-minute changes

For contractors managing aggressive schedules, professional shop drawings become an essential project management asset.

Expert Opinion

Construction delays are expensive, disruptive, and often preventable. Professional shop drawings address the root causes of errors long before they reach the job site. By investing in accuracy, coordination, and expertise, contractors and fabricators protect their schedules, budgets, and reputations.

In today’s construction environment, precision is not optional—it is a competitive advantage.