Modern construction projects operate under intense pressure—compressed schedules, tight budgets, complex coordination requirements, and strict regulatory oversight. In this environment, shop drawings are no longer just technical documents; they are foundational tools that determine whether a project moves forward efficiently or becomes trapped in cycles of rework and delay. Shop drawings translate design intent into precise, actionable instructions that fabricators and installers can rely on with confidence. Without them, even the best architectural or engineering designs can fail during execution.

For contractors and fabricators across the United States, shop drawings are essential to achieving constructability, reducing risk, and maintaining accountability throughout the construction lifecycle.

What Are Shop Drawings?

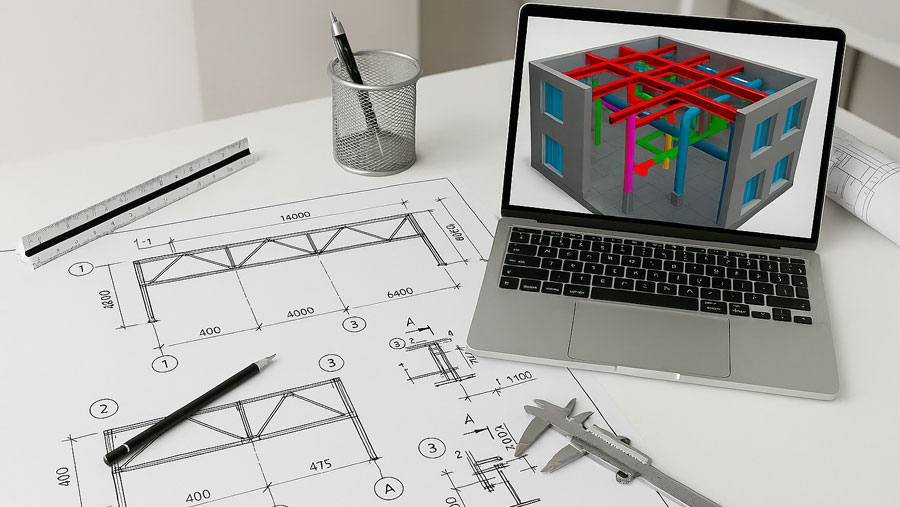

Shop drawings are detailed, discipline-specific drawings prepared to show how individual components of a construction project will be fabricated, assembled, and installed. They go far beyond conceptual design by providing exact dimensions, materials, connection details, tolerances, and sequencing instructions tailored to real-world construction conditions.

Unlike design drawings, which focus on overall intent, shop drawings address how the work will actually be built. They are typically prepared by specialized drafting firms, fabricators, or engineering teams with deep technical knowledge and field awareness.

In practice, shop drawings act as the final technical checkpoint before materials are fabricated and installed on site.

The Role of Shop Drawings in the Construction Workflow

Shop drawing studio sit at the center of coordination between design teams, contractors, fabricators, and inspectors. They ensure that everyone is working from the same, constructible understanding of the project.

At different stages of construction, shop drawings serve critical functions:

- During pre-construction, they help identify conflicts and design gaps.

- During fabrication, they guide manufacturing with exact specifications.

- During installation, they provide installers with clear, step-by-step reference.

- During inspection, they demonstrate compliance with approved designs and codes.

Because of this central role, inaccuracies in shop drawings often have amplified consequences.

Shop Drawings vs Design Drawings vs As-Built Drawings

Construction projects rely on multiple types of drawings, each serving a distinct purpose. Confusing these documents can lead to misaligned expectations and execution errors.

Design Drawings

Design drawings are prepared by architects and engineers during the planning phase. They establish layout, structural intent, performance criteria, and aesthetic direction. However, they intentionally omit fabrication-level detail.

Shop Drawings

Shop drawings convert design intent into build-ready documentation. They include exact dimensions, connection details, material grades, bolt sizes, weld symbols, reinforcement layouts, and installation notes specific to the project conditions.

As-Built Drawings

As-built drawings document what was actually constructed, including any deviations from approved plans. They are essential for facility management, future renovations, and legal documentation.

Each drawing type supports a different phase, but shop drawings are where theoretical design meets physical construction.

Types of Shop Drawings Used in Construction Projects

Different construction trades depend on specialized shop drawings that address their unique technical requirements. High-quality coordination across these drawings is essential for smooth execution.

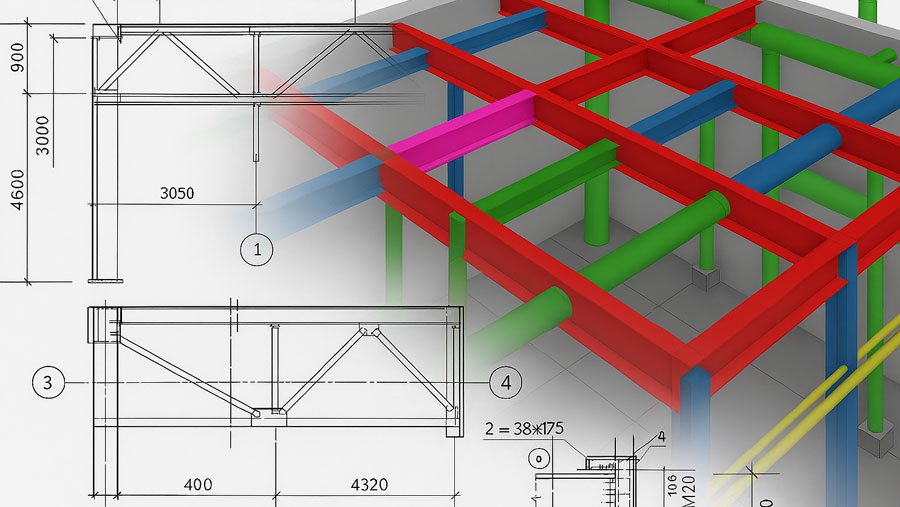

Structural Steel Shop Drawings

These drawings detail beams, columns, braces, base plates, connections, bolt patterns, welds, camber, and erection sequences. Accuracy here is critical because steel components are fabricated off-site and cannot be easily modified later.

Rebar and Concrete Shop Drawings

Rebar shop drawings define bar sizes, spacing, bends, lap lengths, anchorage, and placement sequences. They must align precisely with structural design and local code requirements to ensure strength and durability.

Architectural Shop Drawings

Architectural shop drawings cover elements such as stairs, railings, curtain walls, storefront systems, doors, windows, and custom finishes. These drawings ensure aesthetic intent is achieved without compromising constructability.

MEP Shop Drawings

Mechanical, electrical, and plumbing shop drawings coordinate ductwork, piping, conduits, equipment, and supports. These drawings are essential for avoiding clashes in congested spaces.

Who Prepares Shop Drawings and Why Expertise Matters

Shop drawings should be prepared by experienced detailers and engineers who understand both design principles and field execution. Certified detailers bring technical accuracy, while Professional Engineers add validation, compliance oversight, and accountability.

Expert teams can:

- Interpret design intent correctly

- Identify conflicts early

- Apply applicable U.S. codes and standards

- Produce drawings that withstand review and inspection

Inexperienced preparation often leads to RFIs, revisions, and costly delays downstream.

Common Shop Drawing Mistakes and Their Impact

Mistakes in shop drawings are among the most common causes of construction inefficiencies. These issues typically originate from rushed preparation, lack of coordination, or insufficient technical review.

- Incomplete or missing dimensions

Installers are forced to guess, increasing the risk of errors. - Conflicting details between trades

Structural, architectural, and MEP elements collide on site. - Non-compliance with codes

Drawings are rejected during review, delaying fabrication. - Poor revision control

Outdated drawings lead to incorrect fabrication.

Professional workflows and structured reviews significantly reduce these risks.

How Professional Shop Drawings Improve Project Outcomes

High-quality shop drawings deliver measurable value across the project lifecycle. They reduce uncertainty, accelerate approvals, and support predictable execution.

Key benefits include:

- Fewer RFIs and change orders

- Faster fabrication and installation

- Reduced material waste

- Improved safety through clarity

- Stronger coordination across trades

For U.S. projects operating under strict regulatory and contractual frameworks, these benefits directly impact profitability and reputation.

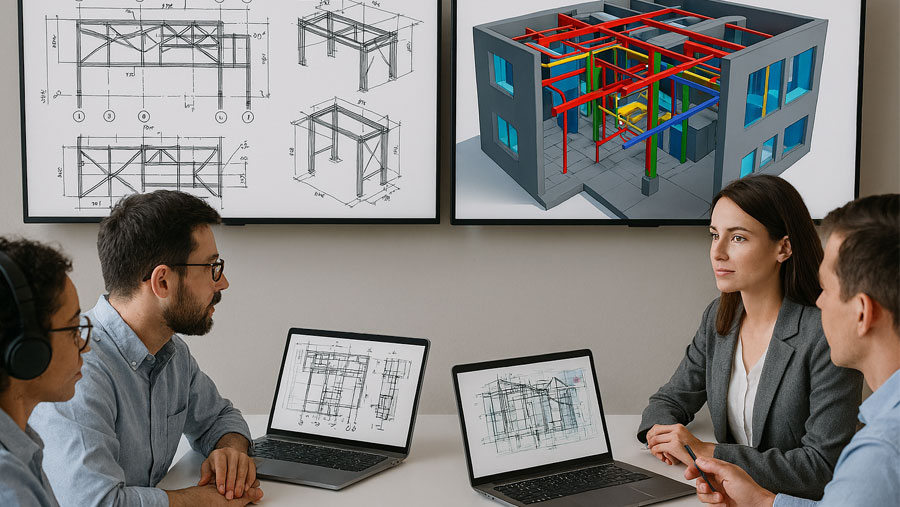

When and Why to Outsource Shop Drawings

Outsourcing shop drawings to a specialized engineering and drafting firm allows contractors and fabricators to focus on execution while ensuring technical excellence. Outsourced teams bring scalability, speed, and specialized expertise that is difficult to maintain in-house year-round.

When done with the right partner, outsourcing transforms shop drawings from a bottleneck into a competitive advantage.